In many regulated industries, such as the food and beverage, pharmaceutical, healthcare, medical device, aerospace, and certain manufacturing industries, maintenance of specific environmental conditions for certain products is a critical part of the manufacturing process.

The cold supply chain, or simply cold chain, refers to the way sensitive materials and products move through the supply chain while being kept at a specified temperature.Transporting these goods in a temperature-controlled environment helps keep the products fresh and effective. This special care also helps to ensure that the product is safe for the consumer to use. The cold chain is vital in allowing these industries to operate and helps keep the general public safe.The cold chain effectively started in the 1920s when refrigerated trucks were used in the ice cream industry to keep their products cold during transport. Today, not only does the world house millions of refrigerated vehicles, but also supports a number of modern technologies to make the cold chain better, easier to manage, and more efficient. Here are five essential cold chain technologies.

1. Refrigerated trucks

Insulated trucks filled with ice to keep food products cold started in the 1920s. A decade or so later the technology that would revolutionize cold chain transportation was invented. That happened in 1938 when famed inventor Fredrick McKinley Jones invented the first portable air-cooling unit for trucks.Jones partnered with entrepreneur Joe Numero to start the company that would become the Thermo King Corporation and, in the process, change the way we transport food. During World War II, these portable air coolers were invaluable for preserving products such as blood and medicine on the frontlines of the war. This helped demonstrate the worth of this cooling technology for other materials that need to be temperature-controlled.The basics of Jones’ cooling units are still found in many refrigerated vans today. What has changed is the addition of technology to make the units more efficient, accurate, and cheaper and greener to run. Additions include solar power, advanced thermal insulation materials, IoT and smart technology in the units, all built on what Jones developed to make refrigerated trucking what it is today.

2. Digital data loggers

Tracking temperatures throughout the cold chain is a very important piece of the system, too. Cooling is one thing, but without monitoring the temperature-controlled environment, you run the risk of system failures, outside elements, or simple hotspots negatively affecting the product. This can lead to wasted product, fines, or even shutdowns if a company violates temperature regulations.Digital data loggers, which companies like Dickson provide, are a primary means of tracking temperature in the cold chain. Data loggers are digital sensors that can precisely monitor environmental conditions such as humidity, pressure, and of course, temperature. Data loggers are internet-connected and can “communicate” with each other and report their data to a central location via cloud-based remote monitoring systems.Data loggers can be used to create a thermal map that shows how temperature varies throughout a storage space. Single-use data loggers can be placed in individual packages to help guarantee that every unit of product stays within a specified temperature limit.

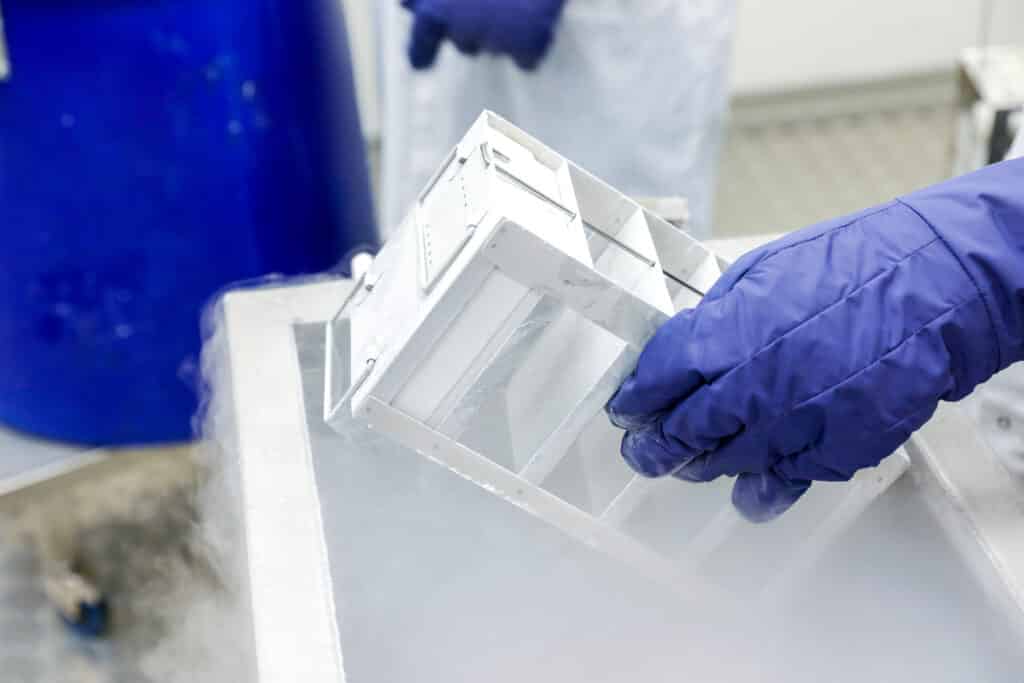

3. Deep Freezers

For some products, just being cold is not enough. Certain products that contain very sensitive material require a deep freeze or cold room. This is very topical technology today. For example, both of the COVID vaccines currently approved for use in the US, use a delicate genetic material known as messenger RNA (mRNA). The fragility of this material means that it has to be transported and stored in a well below zero deep freeze until it is ready to be administered.The good news is, cold chain technology allows materials to be kept at these extremely cold temperatures. These freezers look like normal freezers but are capable of holding their contents at deep-freeze temperatures. For example, one of the popular models of these deep freezers has a range of -86°C to -50°C (-122.8°F to -58°F). The freezers often have additional features that help protect sensitive material such as alarms and emergency battery backup.The need for these freezers for the COVID-19 vaccines has created a huge demand for them. Companies that can produce them are racing to do so. While this is a difficult situation in 2021, the fact is that after this situation is conquered, so many deep freezers will be available it is likely to be a good thing for the future of cold chain.

4. Phase Change Material (PCM) Gel

If you can’t cool an entire space with a cooling system, sometimes you need a material to cool the space for you. In the past, options were limited to ice and dry ice. Technology has helped develop material that is better and more reusable than these other two options. This material is known as PCM.In the cold chain space, PCM comes in gel packets and acts the same way ice does (ice is actually a PCM). When the material changes from a solid to a liquid, or in this case a gel, energy is released and it can cool a space. What makes PCM gel different from ice is that it can be scientifically designed to release energy to cool to different temperatures. It is also reusable and it takes less PCM gel to cool a space than it would ice. It’s also far less messy when it melts.

5. Polyurethane

One of the most technologically advanced insulating materials used today is polyurethane. This polymer is a great insulating material and can hold constant temperatures in shipping packages for long periods of time. It also requires a less thick layer than other materials to achieve the same results which is why it is a favorite of cold chain shippers.

Conclusion

The cold chain has come a long way since those first ice cream trucks were rolled out a century ago. Today, technology, such as solar and smart trucks, data loggers, deep freezers, PCM, and polyurethane are making the cold chain better for all of us and that is a good thing for businesses and consumers alike.