The dawn of affordable 3D printing is set to completely upturn the way we do business.

The ability to use additive layer manufacturing to create new, more efficient and more affordable items no longer requires an investment of tens of thousands of pounds for a single 3D printer.

Now, the revolutionary technology is well within the means of small businesses across the country.

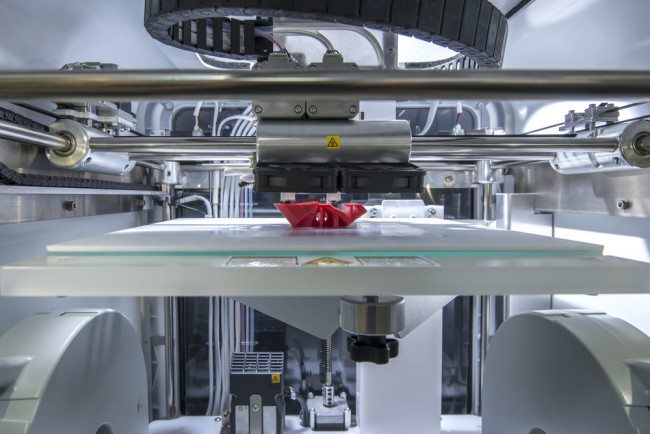

3D printing – or ‘additive layer manufacturing’ – builds items in layers, fractions of millimetres at a time, to form high resolution 3D objects. Traditionally 3D printing has been used to create plastic and metal items, but the range of possible materials, and the 3D printing processes to create them, is broadening.

Within the next three or so years, we should see the 3D printing of fabrics. This has the potential to completely revolutionise textile, fashion and home interiors businesses, to name but a few. Perhaps you notice a jacket you like the look of, but the material’s not for you, or the colour isn’t what you’re after. With brands embracing the rise of domestic 3D printers, you could have your perfect cut, colour and fabric building itself in your living room in a matter of minutes. Fashion brands could also offer bespoke tailoring as the norm, individually printing clothing to fit each customer perfectly. We’re already seeing 3D printed shoes companies making strides in personalised printed apparel.

With 3D printing offering ever-increasing opportunities for small businesses, here are five key ways in which all kinds of SMEs can get in on the revolution:

Prototyping

With 3D printing being vastly more affordable for creating singular objects than employing a third party manufacturer, 3D printing is breaking down the barriers to entry for entrepreneurs by enabling prototypes to be created swiftly and cheaply. Speeding up the design process can be invaluable to young companies, and now even the smallest of businesses can afford to own their own 3D printer to do so. By designing and printing a prototype in a matter of hours, rather than waiting days or weeks for a design to come to life, entrepreneurs can significantly cut down the time they spend working up a viable product.

Re-designing and Personalisation

For small businesses producing branded or personalised merchandise, minimum orders from manufacturers may require the purchasing of hundreds or even thousands of one design. As 3D printing doesn’t demand the re-tooling of machinery – instead simply requiring the uploading of a tweaked design – customised products can be created singularly. By vastly cutting down the overproduction of items, small companies can offer products and enter markets otherwise unaffordable.

Always in stock

Similarly, the ability to produce products or spare parts locally and individually is another way small businesses can capitalise on the recent availability of desktop 3D printers. For example, reducing shipping costs and offshore production costs means that businesses such as garages can afford to print individual spare parts as needed, vastly reducing the waste and repair time and providing a much more streamlined service. Soon, even office equipment could be more affordable if printed on-site.

New horizons

For sectors as diverse as manufacturing companies and healthcare professionals, the most exciting quality of 3D printers is their ability to create shapes otherwise impossible to produce. Moulding, drilling and binding materials and other manufacturing processes simply cannot make certain shapes which additive manufacturing masters. We’ve now seen surgeons using an MRI scan to 3D print a copy of a toddler’s heart, to help them understand how to operate effectively. Shapes available through 3D printing may be also lighter, more effective or more efficient than those created by traditional processes.

Domestic printers offering instant sales

All of these are ways small businesses can capitalise on the affordability of 3D printers for use in-house. However, the fact that 3D printers are now available for as little as a regular 2D desktop printer means that it is not only SMEs that can afford to have them. Domestic 3D printers are now on the rise, and businesses can also make the most of this move into British homes.

In our world of ‘next day delivery’, consumers are expecting goods to be in their hands within shorter and shorter periods. Amazon have already patented plans for delivery trucks containing 3D printers, enabling the creation of purchases en route to a consumer. However, the more exciting opportunity – and most interesting revolution on the horizon for small businesses – is for brands to offer their products as downloadable 3D designs. SMEs can embrace the rise of domestic 3D printers and offer their customers access to products within hours, without them even having to leave their home. Importantly, such designs can also be personalised, with colours chosen, branding and images modified and add-ons readily available.

Such a move will change the world of consumer goods manufacturing as we know it, and hugely impact on retail and delivery industries. We can imagine Amazon shifting towards a marketplace for people to print a whole range of purchases at home, which would completely upturn its existing system of warehouses and delivery services.

These are just five ways in which businesses can capitalise on the rise of affordable 3D printing. The breadth of possibility for creating novel objects quickly, cheaply and efficiently means innovative SMEs can find countless uses for the technology. Once the reserve of sci-fi fantasies, 3D printing is already making waves in a whole range of businesses – the time to get in on the revolution is now.